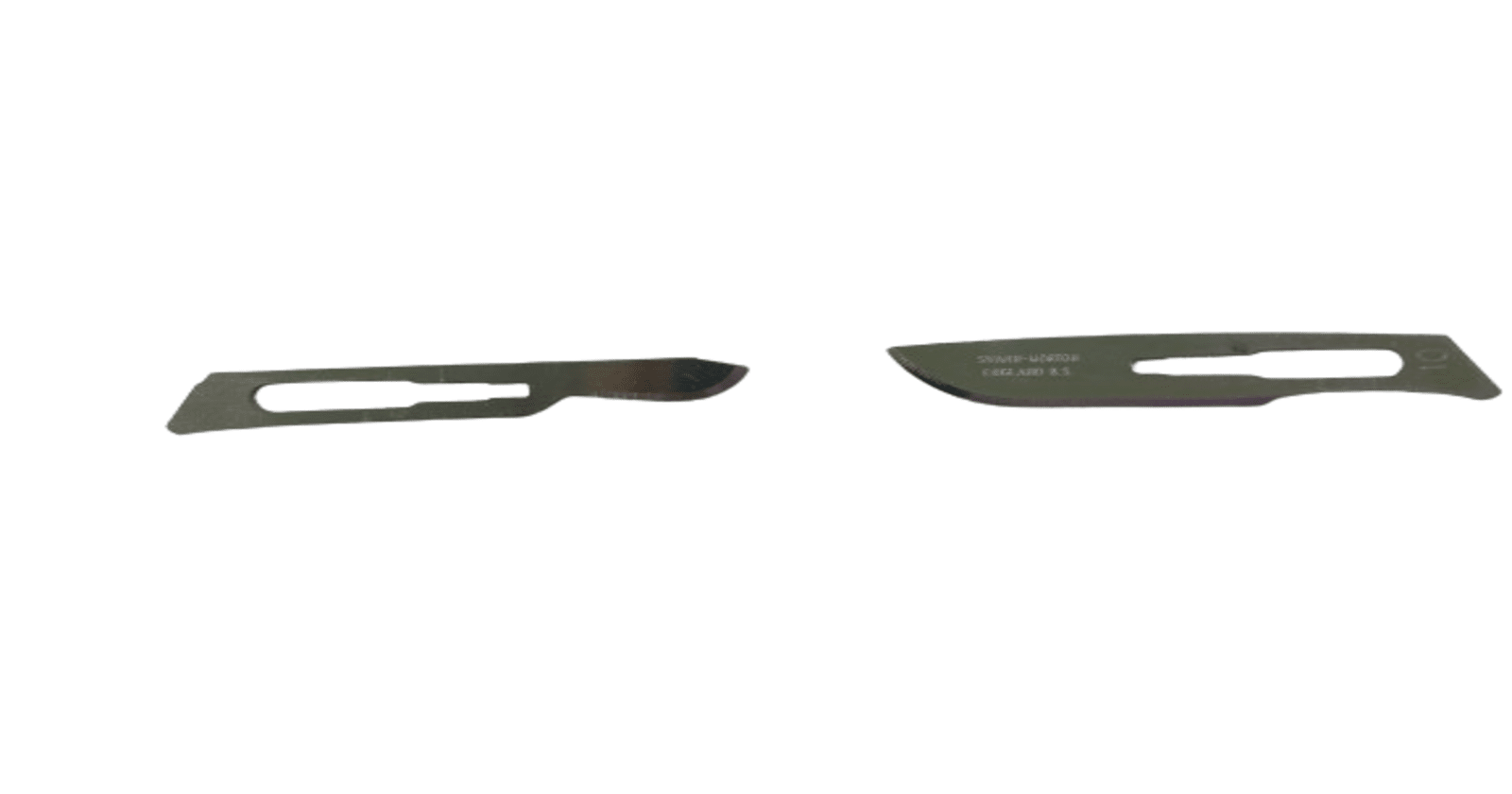

The #10 blade has a curved cutting edge, resembling a small crescent or half-moon shape. The #15 blade has a small, pointed, and triangular shape, used for making small, precise incisions in tight or confined spaces, such as in podiatry or ophthalmic procedures. It’s also used in delicate plastic surgery procedures.

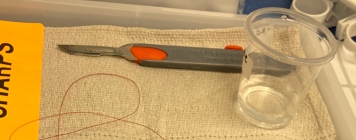

Surgical blades are used in various medical procedures for tasks like making incisions, excisions, and other types of tissue manipulation. The numbers associated with surgical blades, such as #10 and #15, indicate different blade shapes, sizes and uses.

Number #10 surgical blade

The #10 blade is a surgical blade commonly used in various medical procedures. It is characterized by its curved cutting edge, which resembles a small crescent or half-moon shape. This curvature allows for precise and controlled cutting, making it suitable for a range of tasks in surgery and other medical applications.

It is made of stainless steel, which provides durability and corrosion resistance. This ensures that the blade remains sharp and reliable throughout the course of a surgical procedure. The #10 blade typically measures about 3 cm (1.2 inches) in length, with the curved cutting edge forming a gentle arc along one side. The back edge of the blade is straight or slightly curved.

frequently used for making small incisions in delicate tissues, such as during procedures involving skin, mucous membranes, and other soft tissues. It is commonly employed in specialties like general surgery, dermatology, and plastic surgery.

Common Usage of #10 blade

frequently used for making small incisions in delicate tissues, such as during procedures involving skin, mucous membranes, and other soft tissues. It is commonly employed in specialties like general surgery, harvesting the radial artery during a coronary artery bypass operation, opening the bronchus during thoracic surgery, uterine incisions for a C-Section and for Inguinal hernia repair dermatology, and plastic surgery.

It is used for cutting soft tissue, typically with large incisions and surgeries like tonsillectomies, circumcision, and other general surgical procedures. The curved shape of the #10 blade allows for good visibility during incisions. It is mostly Used for first incision or opening of the skin and is sometimes refer to as skin knife.

Sterilization: Like all surgical instruments, the #10 blade must be sterilized before use to ensure aseptic conditions in the operating room. This is typically achieved through methods such as autoclaving or gamma irradiation. The primary methods for sterilizing surgical instruments are dry heat and autoclaving. Autoclaving, a process that utilizes high-pressure saturated steam, is the prevailing and widely employed technique in ensuring the sterility of surgical instruments. Scalpel are sterilize and the individually package.

Limitation of Number #10 Surgical blade

The number 10 surgical blade, like any other medical instrument, has its own set of limitations. Here are some potential limitations:

- Size and Shape: The number 10 blade is relatively small and has a pointed tip. This may limit its use in situations where a larger or differently shaped blade would be more effective.

- Depth of Incision: The size of the number 10 blade may limit its ability to make deep incisions, especially in cases where a deeper or more substantial cut is required.

- Tissue Type: The number 10 blade may not be suitable for cutting through tougher or denser tissues. In such cases, a blade with a different shape or size may be more appropriate.

- Precision: While the number 10 blade is sharp and can make precise incisions, there may be situations where an even finer or more specialized instrument is required for highly detailed work.

- Accessibility: Depending on the surgical site and the angle at which the incision needs to be made, the size and shape of the number 10 blade may limit its accessibility.

- Blade Durability: Like any surgical blade, the number 10 blade can become dull with use, which may necessitate frequent replacement during a procedure.

- Safety Concerns: The sharpness of the blade requires careful handling to avoid accidental cuts to the surgeon or other members of the surgical team.

- Specialized Procedures: Certain surgical procedures may require specialized blades with unique shapes, sizes, or features that the number 10 blade does not possess.

- Electrosurgery Compatibility: The number 10 blade is typically a non-electrosurgical blade, meaning it is not designed for use with electrosurgical devices. In cases where electrocautery is required, a different type of blade or instrument would be needed.

- Specific Surgical Requirements: Some surgical procedures have specific requirements for blade type, size, and shape based on the nature of the procedure and the anatomy involved. The number 10 blade may not always be the most appropriate choice for these cases.

9 Key Tips For safely Handle a Surgical blade

- Wash Hands Thoroughly:

- Always begin by washing your hands thoroughly with soap and water. This helps reduce the risk of infection.

- Use Personal Protective Equipment (PPE):

- Wear appropriate PPE, including gloves and, if necessary, a mask and gown, to protect yourself and the patient from potential infections.

- Inspect the Scalpel:

- Before use, inspect the scalpel for any damage or defects. Ensure that the blade is securely attached to the handle.

- Handle with Care:

- Treat the scalpel with care and respect. Avoid dropping it or mishandling it in any way.

- Hold the Scalpel Properly:

- Hold the scalpel in a pencil grip, with the index and middle fingers on the blade, and the thumb supporting the handle. This grip provides better control and precision.

- Avoid Excessive Force:

- Surgical scalpels are sharp and designed to cut with minimal force. Avoid using excessive force, as this can lead to uncontrolled cuts and potential injuries.

- Always Cut Away from Yourself:

- When making an incision, ensure that you cut away from yourself and others. This reduces the risk of accidentally cutting yourself or someone else.

- Focus on the Task:

- Maintain focus and concentration while using a scalpel. Avoid distractions to prevent errors.

- Dispose Properly:

- Dispose of used scalpels in designated sharps containers. Do not recap the blade, as this increases the risk of accidental injuries.

The Impact of Blade Choice on Wound Healing Times and Scarring: #10 vs. #15 Surgical Blade

#10 Blade Impact on Healing Times and Scarring:

- Healing Times:

- The larger surface area of the #10 blade can create longer incisions, which may take more time to heal compared to smaller incisions.

- Healing time can be longer if the wound requires more extensive suturing or if there’s a higher risk of tension across the wound.

- Scarring:

- Larger incisions made with the #10 blade can potentially result in more noticeable scars due to the greater tissue disruption.

- Scarring may be more pronounced if the incision is not made along natural skin lines or if there is significant movement in the area.

# 15 blade Impact on Healing Times and Scarring:

- Healing Times:

- The #15 blade’s smaller, more precise incisions often heal faster due to less tissue disruption.

- Reduced wound tension typically leads to quicker healing and lower risk of complications.

- Scarring:

- Smaller, more precise incisions usually result in minimal scarring.

- Using the #15 blade can lead to finer, less noticeable scars, especially in areas requiring precision such as the face or hands.

| Blade Type | Details |

|---|---|

| #10 Blade healing time | Longer incisions can take more time to heal. Increased risk of complications if not properly managed. |

| #15 Blade healing time | Smaller, precise incisions generally heal faster. Reduced risk of complications and quicker recovery. |

| #10 Blade scarring | More noticeable scarring due to larger incision size. Important to consider the placement of incisions to minimize scar visibility. |

| #15 Blade scarring | Less noticeable, finer scars. Ideal for procedures requiring minimal scarring, such as cosmetic surgeries. |

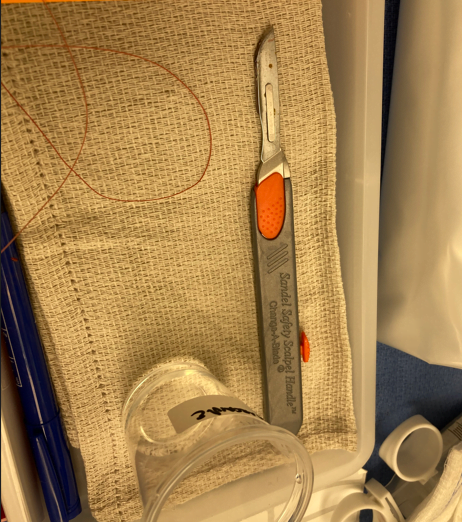

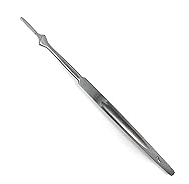

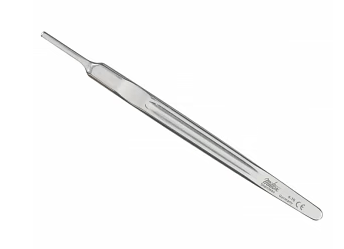

Compatible handle for a #10 blade and #15 blade

The #10 and #15 blade is designed to fit onto a specific handle, usually referred to as a #3 or #3L handle. The blade is attached to the handle via a secure fitting mechanism.

The No.10 fits Handles 3, 3L, 3 Graduated, 5B, 7, 9 and B3.

Safety Features: Some #10 blades may come with safety features, such as a protective sheath or cap to cover the cutting edge when not in use. This helps prevent accidental injuries during handling.

Single-Use vs. Reusable: Depending on the manufacturer and specific use case, #10 blades may be available in both single-use disposable versions or as reusable blades that can be reprocessed and sterilized for multiple uses.

Alternatives: While the #10 blade is widely used, there are other blade shapes and sizes available for specific surgical applications. Surgeons may choose different blades based on factors such as the type of tissue being operated on and the nature of the procedure.

Some handles have a mechanism to lock the blade in place. Make sure it engages properly to secure the blade.

Check for Proper Alignment:

- Verify that the blade is aligned straight with the handle. It should not be crooked or off-center.

Perform a Safety Check:

- Ensure that the blade is firmly attached and will not come loose during use. Gently tug on the blade to confirm it is secure.

Dispose of Packaging and Sharps Safely:

- Dispose of any packaging material and sharps (e.g., protective coverings) in designated biohazard containers.

Attaching a Surgical Blade to a Handle

Attaching a surgical blade to a handle is a precise procedure that requires careful attention to detail. Here are the steps to follow:

- Gather Necessary Supplies:

- Surgical blade

- Compatible surgical handle

- Ensure Sterility:

- Make sure that you are working in a sterile environment wearing appropriate personal protective equipment (PPE) like gloves and a gown.

- Inspect the Blade and Handle:

- Check the blade for any signs of damage or defects. Ensure that the handle is in good condition and functions properly.

- Position the Blade:

- Hold the surgical blade by its non-sharp edges, avoiding contact with the blade’s cutting surface.

- Identify the Correct Orientation:

- Ensure that you have the correct orientation of the blade. Some surgical blades have specific markings or indicators to help with this.

- Locate the Notch or Slot on the Handle:

- Most surgical handles have a notch or slot where the blade will be inserted.

- Align the Blade with the Handle:

- Position the blade so that it aligns with the notch or slot on the handle. The sharp edge of the blade should face outward.

- Insert the Blade:

- Gently slide the blade into the notch or slot on the handle. Apply even pressure, taking care not to force the blade.

- Ensure a Secure Fit:

- Once the blade is inserted, check to ensure that it is seated securely in the handle and that there is no wobbling or movement.

Proper cleaning and sterilization of surgical blades are crucial to prevent infections and ensure patient safety.

Cleaning Procedures

- Pre-Cleaning:

- Immediately after use, rinse the blades with cold water to remove any blood and debris. This helps prevent the drying of biological materials on the instruments.

- Manual Cleaning:

- Use a soft brush and an enzymatic cleaner or a neutral pH detergent to clean the blades thoroughly. Avoid abrasive materials that could damage the blade.

- Ensure all crevices and hard-to-reach areas are cleaned. Pay special attention to joints and hinges.

- Rinse the blades thoroughly with distilled or deionized water to remove all cleaning agents.

- Ultrasonic Cleaning:

- Place the blades in an ultrasonic cleaner filled with an appropriate cleaning solution. This helps remove any remaining debris and contaminants.

- Follow the manufacturer’s instructions regarding cycle times and temperatures.

Sterilization Procedures

- Drying:

- Ensure the blades are completely dry before sterilization. Residual moisture can interfere with the sterilization process and promote corrosion.

- Packaging:

- Wrap the blades in sterilization wraps or place them in sterilization pouches. Ensure the packaging is intact and properly sealed to maintain sterility after the process.

- Sterilization Methods:

- Steam Sterilization (Autoclaving):

- Place the packaged blades in an autoclave. Ensure that the autoclave is not overloaded to allow proper steam penetration.

- Follow the autoclave manufacturer’s guidelines for temperature and cycle duration. Typically, the recommended settings are 121°C (250°F) for 30 minutes or 134°C (273°F) for 3-5 minutes.

- Dry Heat Sterilization:

- For instruments that cannot be exposed to moisture, use dry heat sterilization. Follow the manufacturer’s guidelines for temperature and cycle duration. Typically, 160°C (320°F) for 2 hours or 170°C (340°F) for 1 hour is recommended.

- Chemical Sterilization:

- Use chemical sterilants like ethylene oxide or hydrogen peroxide plasma for heat-sensitive instruments. Follow the manufacturer’s instructions for exposure times and conditions.

- Steam Sterilization (Autoclaving):

Maintenance

- Inspection:

- After sterilization, inspect the blades for any signs of damage, corrosion, or wear. Replace any blades that show signs of compromise.

- Sharpening:

- Regularly sharpen blades to maintain their effectiveness. Use appropriate sharpening tools and techniques to avoid damaging the blades.

- Storage:

- Store sterilized blades in a clean, dry, and sterile environment. Use dedicated storage containers to protect the blades from contamination and physical damage.

Number #15 surgical blade

The #15 blade is a surgical blade commonly used in medical procedures. It is characterized by its small, pointed, and triangular shape, which allows for precision cutting in tight spaces. The sharpness of the blade is crucial for achieving clean and accurate incisions. It is designed for detailed, fine work.

Due to its pointed and triangular design, the #15 blade is often used for procedures that require fine, detailed work, such as delicate tissue dissection, microsurgery, and ophthalmic surgery. It is also utilized in procedures where access may be limited or where a smaller incision is preferred.

Additionally, the #15 blade is commonly used in specialties like dermatology for procedures such as mole removal or other skin-related surgeries. Its sharpness and precision make it a versatile tool in the hands of skilled medical professionals.

It’s important to note that surgical blades, including the #15, should be handled with care to avoid accidental injuries. Proper disposal procedures should also be followed to ensure the safety of both healthcare professionals and patients.

Common Usage of #15 blade

The #15 scalpel blade is commonly used in surgical procedures that require precise and controlled incisions. It is particularly favored in procedures involving small and delicate tissues, such as ophthalmic surgery, podiatry, and various types of plastic surgery. Additionally, the #15 scalpel blade may be utilized in procedures where fine dissection and accuracy are crucial, making it a versatile tool in a range of surgical specialties.

- Precision:

- It provides excellent control and precision due to its pointed tip.

- Visibility:

- The pointed tip allows for very precise incisions, but it may require more careful handling for optimal visibility.

- Specialized Applications:

- The #15 blade is often used in specialties where precision is crucial, such as in ophthalmology, plastic surgery, and podiatry.

Modified Number #15 Blade

Number #15c blade:

This specialized blade, slimmer and more streamlined than the conventional #15 blade, features an elongated cutting edge with a gentle curve and a sharper taper. It excels in precision work on small lesions or intricate areas like the alar folds, nose, perioral, periorbital, and auricular regions, where a finer cutting edge is essential. Additionally, it can be beneficial for tasks involving nails and hands.

2. Number#15 T blade:

This specialized tool features a compact, rounded cutting edge with a tapered point, providing enhanced durability. It is well-suited for delicate procedures on both hands and feet, such as precise debridement and the gentle removal of soft corns, minimizing the risk of any collateral tissue damage.

3. Sabre D/15 blade:

A blade with a closed edge and a petite cutting surface, designed for making precise incisions of less than 5 centimeters on sensitive or intricate areas.

Limitation of number #15 surgical blade

While the #15 blade is a versatile tool with many applications, it does have some limitations:

- Limited Strength for Tough Tissues: Due to its small size and delicate design, the #15 blade may not be suitable for cutting through dense or fibrous tissues. In cases where tougher tissues need to be incised, a larger and more robust blade may be necessary.

- Risk of Breakage: The #15 blade is relatively thin and delicate, which makes it more susceptible to bending or breaking compared to thicker, sturdier blades. Care must be taken when using it to avoid excessive force that could lead to blade damage.

- Restricted to Fine Detail Work: While the #15 blade excels at precision work and fine dissections, it may not be the best choice for larger, more substantial incisions. In such cases, larger blades with greater cutting surfaces are typically preferred.

- Not Suitable for Heavy Duty Procedures: Procedures that involve significant cutting, such as joint replacement surgeries or major organ surgeries, usually require larger and more robust blades with higher cutting capacities.

- Potential for Accidental Injury: The sharpness of the #15 blade means that it poses a higher risk of accidental cuts or injuries if not handled properly. Careful attention to safety protocols and proper handling techniques are essential.

- Limited Visibility in Deep Incisions: Due to its small size, the #15 blade may not provide optimal visibility in deep incisions or during procedures where a larger blade might afford better visibility of the surgical field.

- Skill and Experience Required: The use of the #15 blade requires a steady hand and a high level of surgical skill and experience. In less experienced hands, there is a risk of less precise incisions or unintentional tissue damage.

It’s important for healthcare professionals to carefully consider these limitations and select the appropriate blade for each specific procedure based on the type of tissue, surgical approach, and required level of precision.

Shelf life of Surgical Blade

The shelf life of surgical blades can vary depending on several factors, including the type of blade, the manufacturer’s recommendations, and how they are stored. In general, most surgical blades are sterile when they are packaged, and their shelf life is determined by the sterility assurance level (SAL) of the packaging.

Commonly, surgical blades are individually wrapped in a sterile package made of materials like foil or plastic. These packages are sealed to prevent contamination. The expiration date or shelf life will be specified by the manufacturer on the packaging.

It’s important to follow the manufacturer’s guidelines for storage and use. Improper storage, exposure to moisture, or damage to the packaging can compromise the sterility of the blades, potentially rendering them unsafe for surgical use even if they are within their stated shelf life.

It’s crucial to check the packaging for the expiration date and follow any specific storage instructions provided by the manufacturer. If a blade is past its expiration date or if the packaging is compromised, it should not be used for surgical procedures. Always consult with healthcare professionals or relevant authorities for specific guidelines regarding medical equipment and supplies.

Questions and answers that the public often ask about surgical blades:

1. What are surgical blades used for?

Answer: Surgical blades are used for making precise incisions in tissues during surgeries and other medical procedures. They come in various shapes and sizes, each designed for specific types of cuts.

2. Are surgical blades reusable?

Answer: Most surgical blades are designed for single use to ensure maximum sharpness and sterility. Reusing blades can increase the risk of infection and reduce the effectiveness of the blade.

3. What materials are surgical blades made from?

Answer: Surgical blades are typically made from high-quality stainless steel or carbon steel. These materials provide the necessary sharpness and strength required for precise cutting.

4. How are surgical blades sterilized?

Answer: Surgical blades are usually pre-sterilized and packaged individually. They undergo sterilization processes such as gamma radiation or ethylene oxide gas to ensure they are free from bacteria and viruses before use.

5. Why is the sharpness of surgical blades important?

Answer: Sharpness is crucial for making clean, precise cuts, which minimizes tissue damage, reduces bleeding, and promotes faster healing. Dull blades can cause unnecessary trauma to tissues.

6. How do surgeons choose the right blade?

Answer: Surgeons choose blades based on the type of procedure, the specific tissues involved, and the required precision. For example, a #10 blade might be used for large incisions, while a #11 blade is used for stab incisions or delicate cuts.

7. What are the different types of surgical blades?

Answer: There are various types of surgical blades, including:

- #10 Blade: General-purpose blade for large incisions.

- #11 Blade: Pointed blade for precise cuts and stab incisions.

- #15 Blade: Small blade for fine, detailed cuts.

- #20 Blade: Larger version of the #10 blade for extensive cuts.

8. Can surgical blades cause allergies?

Answer: Surgical blades themselves do not typically cause allergies. However, some individuals might be allergic to the latex or other materials used in surgical gloves or equipment. Always inform your medical team of any known allergies.

9. What happens to surgical blades after use?

Answer: Used surgical blades are disposed of in sharps containers to prevent injury and contamination. They are then handled as medical waste and disposed of according to regulatory guidelines.

10. Are there alternatives to traditional surgical blades?

Answer: Yes, alternatives include laser scalpels and ultrasonic scalpels. These tools offer different benefits, such as reduced bleeding and improved precision, but the choice depends on the specific requirements of the procedure.

Resources

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6128153/

https://www.huidainstrument.com/info/what-is-a-10-blade-in-surgery-77889525.html

https://www.wpiinc.com/blog/post/quick-ref-for-sterilization-surgical-instruments

https://www.researchgate.net/publication/327558101_Anatomy_and_Applications_of_the_15_Scalpel_Blade